Inside the Manufacturing Process of Crystal Cat Litter: From Silica Gel to Kitty Comfort

Introduction:

Crystal cat litter has gained popularity among pet owners for its excellent odor control and absorbency. Ever wondered how this innovative cat litter is produced? In this article, we'll take a closer look at the manufacturing process of crystal cat litter, unraveling the journey from raw materials to the final product that provides a comfortable and efficient solution for both cats and their owners.

1. Raw Material: Silica Gel

The primary ingredient in crystal cat litter is silica gel, a porous and absorbent material. Silica gel is derived from silica sand, a naturally occurring mineral. The sand undergoes a series of processing steps, including washing and drying, to extract the silica gel. This raw material sets the foundation for the exceptional absorbency that crystal cat litter is known for.

2. Processing and Granulation:

Once the silica gel is obtained, it goes through a granulation process. This involves breaking down the silica gel into smaller, uniform particles. The granulation process is crucial for creating a litter with consistent absorbent properties. The resulting granules are then sifted to ensure a specific size range, optimizing the litter's performance.

3. Drying and Activation:

The granules are subjected to a drying process to remove any residual moisture. This step is essential for enhancing the absorbency of the silica gel. Additionally, some manufacturers use an activation process, which involves heating the granules to increase their effectiveness in trapping and controlling odors.

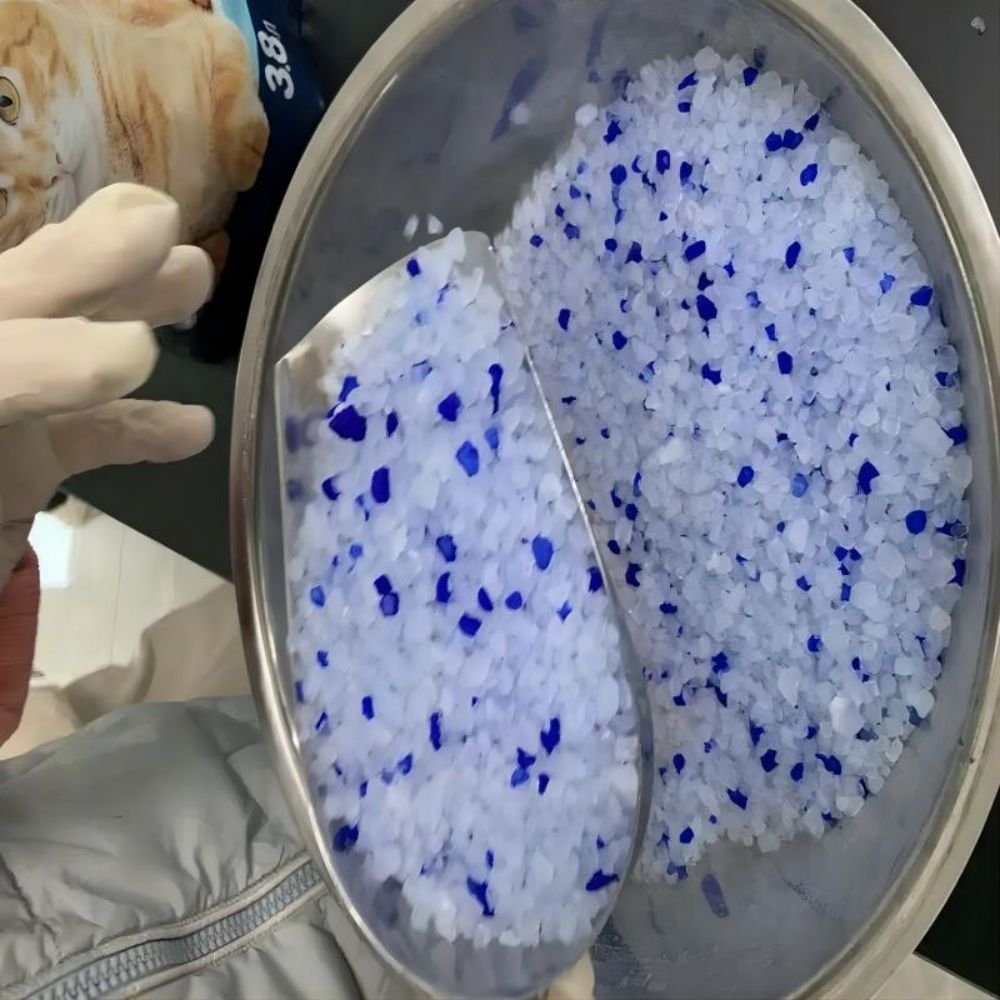

4. Scent and Color Additives (Optional):

To enhance the overall user experience, some crystal cat litters undergo the addition of scent and color additives. These additives are often optional and depend on the brand or product line. While the primary focus is on maintaining functionality, these enhancements can make the litter more appealing to pet owners.

5. Packaging:

Once the crystal cat litter has undergone the necessary processing steps, it is ready for packaging. The litter is carefully packed into bags or containers, ensuring that it remains dry and free-flowing. Packaging may also include information about recommended usage, disposal, and any specific features of the product.

6. Quality Control:

Throughout the manufacturing process, rigorous quality control measures are implemented. This includes testing the absorbency, particle size, and overall performance of the crystal cat litter. Quality control ensures that each batch of litter meets the standards set by the manufacturer, providing a consistent and reliable product for consumers.

Conclusion:

The production process of crystal cat litter involves transforming raw silica gel into a high-performance and user-friendly product. From the initial extraction of silica gel from natural sources to the final packaging, each step plays a crucial role in creating a cat litter that effectively manages moisture and eliminates odors. Understanding the intricacies of this manufacturing process sheds light on why crystal cat litter has become a popular choice among pet owners seeking a clean, low-maintenance solution for their feline companions.

Contact: Bonny Zhu

Phone: +8613854893387

E-mail: info@silica-gel.co

Add: Wanda plaza, Taian City, Shandong Province,China